Instruction of Self-Adhesive Smart PDLC Film Installation

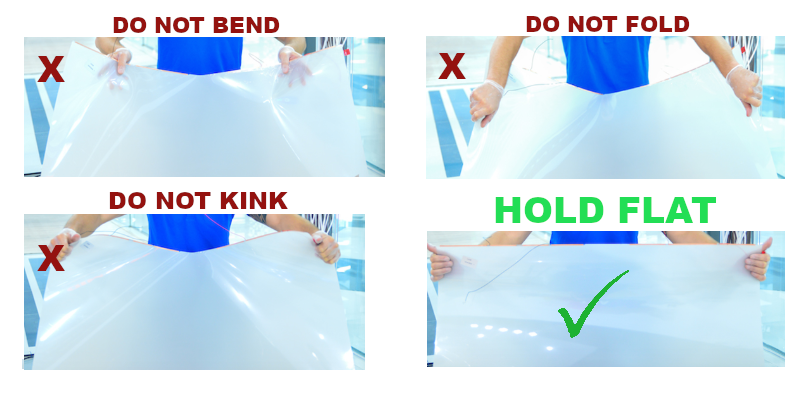

- Keep Smart FILM flat and straight at all times. Don’t let the FILM fold in any way, that will severely damage the Film.

- This FILM needs dry installation

Adhesive privacy film should be stick on glass only. Not on PC or plastic.

DO NOT use water under any circumstances – self-adhesive can be installed using 99% isopropyl alcohol (medical alcohol) only.

The alcohol should be sprayed lightly as an install aid only.

DO NOT start installation until it is 100% dry!

- Keep your working environment as clean and dust-free as possible for optimal results.

- When measuring the outer dimensions, the Smart FILM should be 2-3mm shorter than the glass area.

- The Smart FILM’s protective layer of the non-adhesive side should be kept on the installation until the installation process is completely finished.

- You may wear nitrile gloves during installation; remove the adhesive side of the protective layer before starting the installation.

- Handle the Smart FILM at the edges to avoid separating layers prematurely.

- Use 65V AC power to the FILM with our transformer or other certified transformer. Each transformer covers different area depends on its Watt parameter.

- The electrical contact strip (“Busbar”) or the FILM edges should NEVER be in contact with the metal frame.

- Don’t pull together the busbar wire as it causes a shortcut! The busbar is easy to pull separate with the FILM or glass!

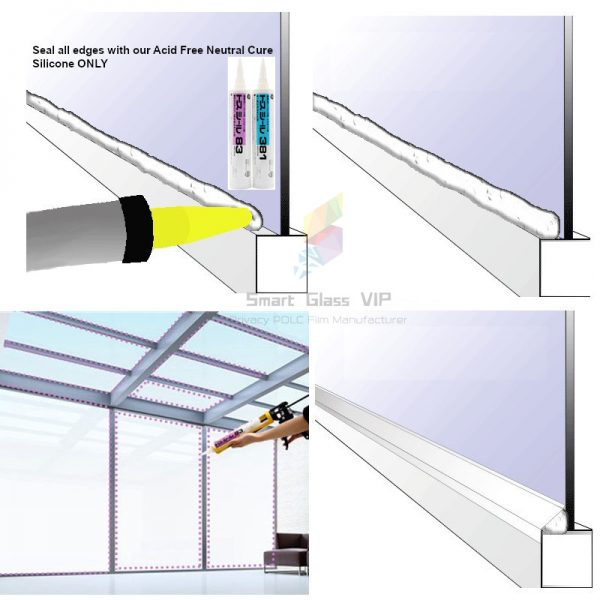

- After installation use only Neutral Silicon A silicone with no ACID. Any other Silicone will damage the FILM

- The Adhesive film should be used INDOOR only with no exposure to direct sunlight (Unless you are using our High Temperature Smart film)

Tools & Materials Required

- Plastic scraper

- Dust-free rubber roller

- Small hand “squeegee” (tendon scraper)

- Nitrile gloves

- Lint-free cleaning cloths

- Transparent glass cleaner (anti-static, anti-fog,dust-proof)

- 99% Isopropyl alcohol

- Neutral Silicon Sealant (Toshiba 381, Dow Corning799)

- Box cutter

Also, very useful to get our installation kit:

These two tools using for remove the bubble. The green one is hard and probably better to remove. It is up to installer.

Installation Procedure

Note: It is recommended not to turn on air conditioner during installation

Part 1: Preparing the Smart FILM

Step 1.1: Open the box and place the Smart Self-Adhesive Film (“FILM”) on a clean flat surface.

Step 1.2: Ensure that the adhesive side is facing up. Do not remove the protective layer until you are instructed in this procedure to do so. The adhesive side is usually marked with a label or a red stamp.

Note:

When touching the self-adhesive side, the surface is little sticky, on the other side, no self-adhesive function, the surface is smooth. If there is some dirt on the surface, you can use alcohol to clean. Don’t worry, the self-adhesive function will be working well still.

Step 1.3: Testing the FILM (by assessing whether it turns on and off). Connect wires into transformer.

Part 2: Clean the Glass Surface

Step 2.1: Using the liquid spray cleaner, spray the glass and use a cleaning roller to remove any dust and/or blemishes for optimal installation. Wipe the glass clean with a clean absorbent cloth. The surface of the glass should be completely smooth and immaculate. Repeat this step as necessary.

Step 2.2: Using a soft, lint-free cloth, wipe the glass surface with isopropyl alcohol. Let this set-up last so that the alcohol may evaporate.

Note:

For clean the glass, alcohol is better than transparent glass cleaner but also could use glass cleaner spray. An experienced installer, use alcohol less since need lot of alcohol and alcohol is easy to evaporate. Normally one spray cleaner bottle could clean 8 sqm of glass. With Spray cleaner, you need to remove the water from glass liquid cleaner and then stick film on the glass.

Note:

FILM may be installed wet only by using 99% isopropyl alcohol only. Do not use water and soak. The alcohol should be sprayed lightly as an installation aid only.

Do not continue until it is 100% dry!

Step 2.3: Using a soft, lint-free cloth, wipe down the protective layer on the adhesive side of the FILM to remove any dust or contaminants, as seen below.

Step 2.4: Very carefully, peel back the first 3-4 inches of the protective layer that is covering the adhesive side. Be sure that no dust falls onto the adhesive side during this step.

Step 2.5: As seen in the photos below, align the self-adhesive FILM edge with the top edge of the glass. When the FILM is perfectly in position, run your finger along the top while pressing own on the FILM so that the applied self-adhesive will hold the FILM in position.

Note:

The glue on the FILM layer is not very strong on first touch. After alcohol is used to clean the glass firmly, and after one sticks the FILM onto the glass, the glue will then be very strong.

Step 2.6: Pull away the protective layer slowly and allow the FILM to adhere to the glass under its own weight. Starting at the top, use the roller in a horizontal (side-to- side) motion, gradually moving down the glass to disperse any air bubbles. If air bubbles still persist, carefully lift the FILM, check if any dust particles have stuck to the adhesive side and remove them with adhesive tape if so, and let the FILM settle again without air bubbles. See photos below.

You do not need to connect film to power supply to see bubble. Once installed ,if having bubble, it is easy to see it.

Step 2.7: Repeat the process (starting with step 2.5) until the installation is free of any air bubbles. Step 2.8 (below) should be paid close attention to, should air bubbles be trapped on the edges of the FILM.

Step 2.8: Use the soft-edge squeegee to remove any trapped air bubbles on the FILM’s edges. If any edges appear to be lifting slightly, the edges will relax once the protective layer is completely removed.

Part 3: Testing and connecting to Power

Step 3.1: Each FILM has busbar and a short wire on it. If you need additional wire, you may purchase regular wires from a local hardware store and solder to the existing wire.

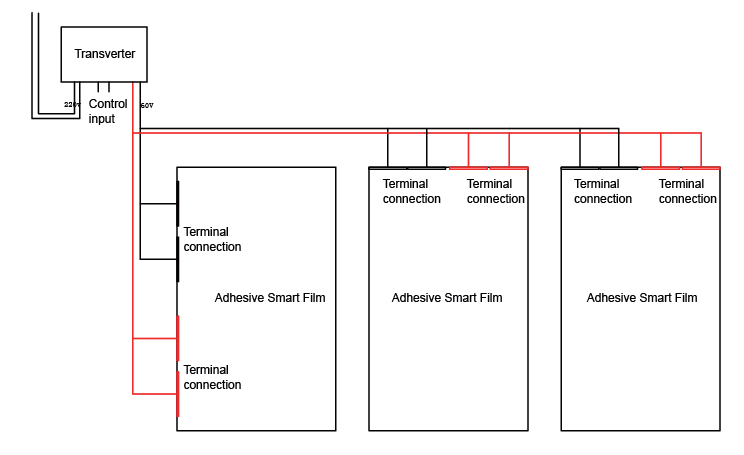

Step 3.2: Connecting to power. We have 230-65v AC and 115-65v AC controller types. Notes:

- In some remotes, there are no batteries included with the remote

- You may also install a wall switch or a remote switch

Step 3.3: Gathering several films to one transformer.

Part 5: Finishing Touches

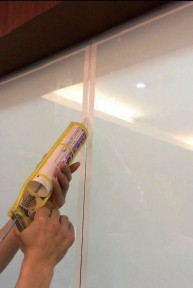

Step 5.1: Use Neutral Silicone Sealant (No Acid) along the FILM edges. First, stick the tape on the edge of the FILM (2mm shorter than the edge of the FILM). Then, apply the silicone glue on the edge of the FILM and use the small hand squeegee to ensure the silicone glue is applied equally smoothly everywhere. Finally, remove the tape from the FILM.

Note:

There are many colors for every Silicone brand. We recommend to use Translucent Silicone.

Note:

If you do not use Neutral Silicone, any damage to the FILM (such as delamination) is not under our product warranty.

As pictured above, stick normal tape on all the edge sides of the FILM.

Then use silicone glue to seal it, as shown above. Finally, make silicone glue smooth and clean.

Step 5.2: Let silicone glue dry for a minimum of one day.

Congratulations…your installation is now complete!

Cleaning

Please clean Smart FILM with spray alcohol or a wet dust-free paper/high-quality towel, then clean and wipe glass.

Troubleshooting

What if the window was not clean well before we stick the film?

Normally you should first spend more than one hour, even two- three hours to clean glass. Then sticking is very easy and there is no reason to take it out.

After taking out the film, the glue will be a bit weaker and the film will lose a bit its toughness, especially with the big films. The film was designed for one stick only.

Additional Note

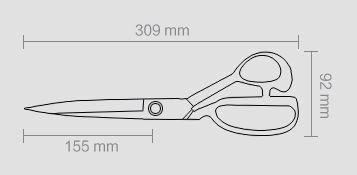

Normally, it is not best to use scissors to cut the PDLC Smart FILM. Professional cutting machine should cut the smart FILM for best results. If one must use normal scissors to re-size the smart FILM, please use professional tailor’s scissors, as pictured below.

However, even if one uses professional tailor’s scissors, our company still cannot 100% guarantee that the PDLC FILM application process will be problem-free and optimal. Cutting the FILM by oneself is not covered under our product guarantee. Our suggestion, that is covered under our guarantee, is that one arranges to cut the FILM using a professional cutting machine.

Professional Tailor’s Scissors